2023-07-22

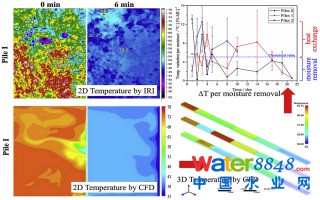

焦点提醒:Effects of aeration on matrix temperature by infrared thermal imager and computational�ײ�APP fluid dynamics during sludge bio-dryingDawei Yua, b, Ming Yanga, b, Lu Qia, b, Mengmeng Liua, b, Yawei Wanga, b, Yuansong Weia, b, The pile temperature in a full-scale bio-drying plants were systematically studied. Infra Thermogram Image was applied to investigate the surface temperature rapidly. Interior temperature during aeration was simulated by Computational Fluid Dynamics. FAS affects microscopic temperature, while condensation affects macroscopic matrix. Theory minimum value of temperature drop is 5.38°C per 1% moisture removal. The effect of aeration on the pile matrix temperature was investigated using thermocouples and Infrared Thermal Imager (IRI) for temperature sensing, and Computational Fluid Dynamics (CFD) for modelling of temperature variation during aeration in a full-scale sludge biodrying plant. With aeration saving of 20%, the improved strategy speeded up biodrying from 21 days to 14 days, while achieving similar drying effect. A persistent thermocouple recorded the one-dimensional (1D) total temperature variation of all aeration strategies. The IRI captured the rapid two-dimensional (2D) pile temperature dropped from 72.5°C to 30.3°C during 6min of aeration, which mechanism suggested as the latent heat of moisture evaporation and sensible heat of air exchange. The CFD three-dimensional (3D) CFD results highlight the importance of latent heat rather than sensible heat. Therefore, the pile temperature drop inferred is ΔT=5.38°C theoretically and ΔT=5.17±4.56°C practically, per unit of MC removed. These findings also emphasize the possibility of a pile temperature valley, due to excessive aeration under unsaturated vapour conditions. Surface temperature monitored by IRI coupled with 3D temperature simulated by CFD rapidly gives a clear matrix temperature evolution, empowering biodrying by more accurate temperature and aeration.

Effects of aeration on matrix temperature by infrared thermal imager and computational fluid dynamics during sludge bio-drying

Highlights

Abstract

Graphical abstract

Keywords